Story

A STORY SPANNING 70 GLORIOUS YEARS

Giuseppe Lorandi was born in 1923, and developped a keen interest in engineering as a boy, tackling repairs on farming machinery and helping his parents in their farming business.

After the war in 1946, Giuseppe and his brother decided to rent a small storeroom, and borrowed a few tools and equipment to start a business repairing farm machinery.

They stopped working with farm machinery in 1948 and, with larger premises and 5 workers, they started to convert the Dodge HGVs left behind by the Americans during the war into lorries to load and unload sand in quarries. Clearly this was of considerable use in an Italy that was undergoing so much reconstruction.

In 1950 the brothers realised they were made for different things.

Giuseppe left the business to go out on his own, and went back to his former passion – the world of farming. He started by repairing farming machinery and constructing iron wheels for tractors in a small workshop that was also home, but this didn’t deter his wife Linda, who always encouraged him to keep working for himself no matter the sacrifice required. Indeed as well as bringing up two children in the house-cum-workshop, she would make up bundles of wood she gathered in the fields and sell them as firewood, just to earn some extra.

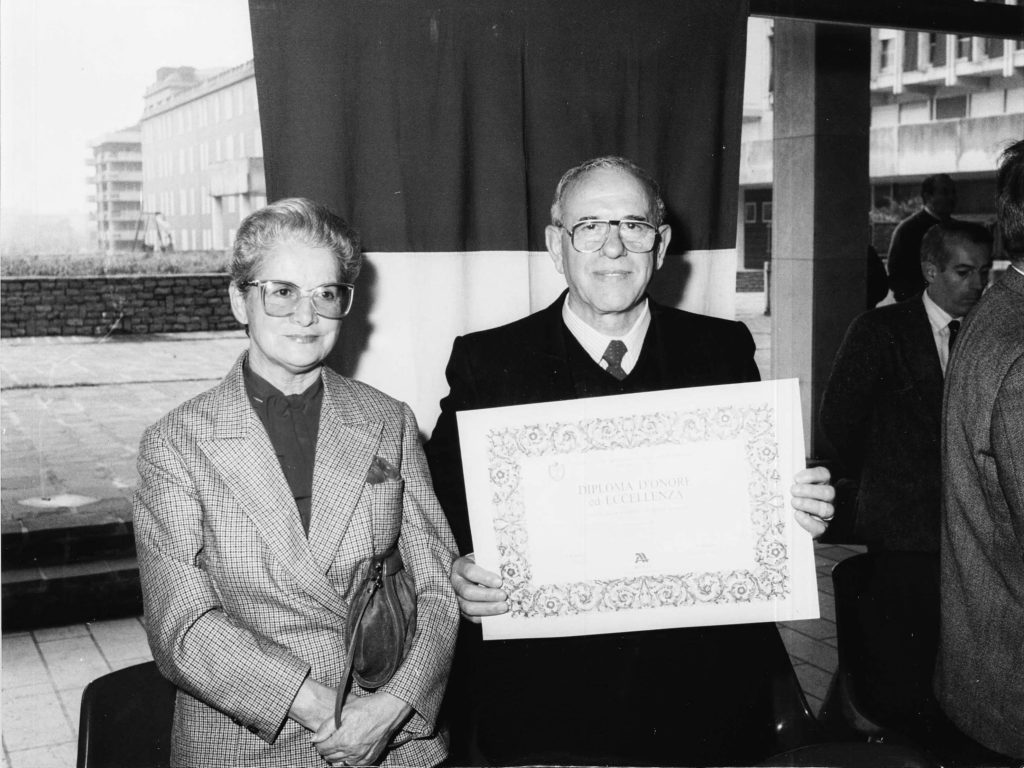

In 1952 he set up the company Lorandi Giuseppe & C., repairing and building farming machinery, and focused on designing and constructing a tractor-mounted drag harrow, for which he obtained a patent.

He purchased land in 1955, which the family still owns, and in two years he built a house and a separate workshop.

In 1957 Giuseppe had an idea – construct a machine to spread manure in the fields. Muck-spreading was of vital importance in farming, but in the1950s nobody wanted to do this unpleasant task any longer.

After numerous attempts, he constructed the first muck spreader. It was presented for the first time at the agricultural trade fair in Verona in 1957 and was a resounding success, with 20 units sold against 7 estimated.

In 1958 the same machine was presented in Verona, but a roller platform had been created to simulate the motion of the machinery in the field, so people could get a better idea of how it actually worked, making it more appealing. He was sure that there, it would be a repeat of the previous year with the sale of 20 units, but in actual fact 80 were ordered.

Muck spreaders weren’t the only product available, there were still the standard harrows, carts for transporting grain, and carts for transporting food from storerooms to troughs to complete the product range.

Continually attending the Verona fair and other fairs in Italy, he met a successful businessman who made raffia sacks for holding animal feed. These containers had stability issues, as they were 3 metres in diameter, approximately 7 in height and had no supporting frame, so they often tipped over onto tractors or farmers.

This businessman became a good friend, and suggested constructing metal silos.

It was 1960 and the company Lorandi started producing its first silos in sheet metal. Son Luciano also joined the company, and brought excellent business skills.

With considerable effort they bought special machines to produce circular sheets and edging machinery.

In addition to silos, 100% he produced also stainless steel tanks for wine and oil.

In 1970 the production was complete with mixers for agricultural products, animal feed mills for the animal husbandry industry, and various types of auger.

Along with the augers, Luciano started successfully producing and selling pneumatic transport systems, i.e. transport for agricultural products with systems that propel containers through networks of tubes by compressed air.

The activities involving silos, augers, pneumatic transport systems and animal feed mills took the place of farming machinery, which was no longer produced.

Luciano set up his own company in 1977, working alongside Lorandi Giuseppe with a different focus – Giuseppe mainly built silos and tanks and Luciano focused on pneumatic transport, mixers and handling loose, dry materials.

These separate yet combined operations continued as Lorando Silos until 1983, when the two businesses merged into one and became Lorandi Luciano.

The 1980s saw a gradual move away from farming, with all focus shifting to plastics and food for human consumption, with the construction of silos and plants for plastic granules and powder, and foodstuffs such as sugar, semolina, coffee and powdered milk.

Today it is Stefano Lorandi, the third generation of the family, who leads the company that started out in agriculture and that today stands out in high-tech plants for the plastics industry, especially regeneration, exported all over the world. Stefano Lorandi also directly oversees the Indian branch, which represents an investment in opening up the company to the evolving Asian markets.